Suitable for all kinds of die steel, aluminum mold, stainless steel, cymbal steel, precious metals and very hard materials. Suitable for welding a variety of materials: S136, NAK80, 718, 738, P20, SKD-11, SKD-61, H13, W302, GS2344, GS2343, GS2082, and other mold steels in various countries.

● Suitable for all kinds of die steel, aluminum mold, stainless steel, cymbal steel, precious metals and very hard materials.

● Suitable for welding a variety of materials: S136, NAK80, 718, 738, P20, SKD-11, SKD-61, H13, W302, GS2344, GS2343, GS2082, and other mold steels in various countries.

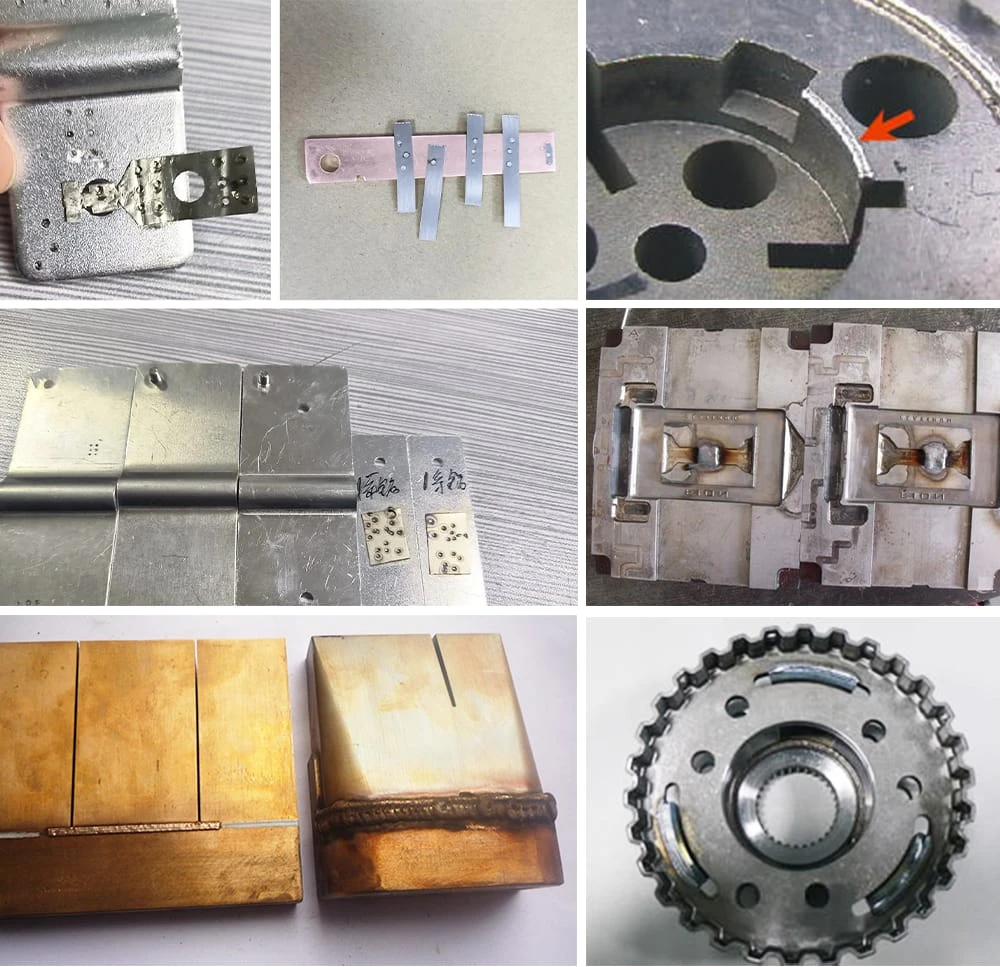

● Commonly used in cell phones, digital products, glasses, toys and other mold manufacturing and molding industry. Precision injection molding, die casting, mold repair metal jewelry and accessories, precision stamping parts welding, lost wax castings, aluminum castings, stainless steel sand hole repair.

● Mainly used in cell phone shielding cover, metal cell phone shell, metal capacitor shell, metal shielding network within the computer, razor blade, electronic connectors and other categories of electronic products, high-efficiency laser spot welding or sealing welding, mold repair and so on.

Equipment performance characteristics / Feature

● Adopt high quality gold-plated spotlight cavity, corrosion resistance, high temperature resistance, life (8-10) years, xenon lamp life of more than 8 million times.

● Adoption of advanced automatic shading system, eliminating eye irritation during working hours.

● XYZ adjustment is suitable for welding of various workpieces.

● laser welding machine is composed of YAG solid-state laser, laser power supply, refrigeration system, laser indication system, operating cabinet and so on.

● Laser welding speed, high efficiency, large welding depth, small deformation, weld seam beautiful, beautiful.

● It can weld hard-to-melt materials and carry out precision welding of micro and small parts.

● It can weld hard-to-reach parts and perform non-contact long-distance welding with great flexibility.

| Equipment Model | RL-LM400-R-G |

|---|---|

| Output power | Max 400W(Continuously Adjustable) |

| Laser wavelength | 1060-1070nm |

| Power Stability | ±2% |

| Focusing Cavity | Ceramic gold-plated chamber*2 |

| Cooling mode | Water cooling |

| Peak Power | 18KW |

| Maximum pulse energy | 100J |

| Pulse Width | 0.5-20ms |

| Pulse Frequency | 1-50Hz |

| Wire Size | 0.2-2mm |

| Viewing System | Binocular system |

| Table travel | X=125mm, Y=100mm Working table size: 300*400mm |

| Table lift stroke | Z-axis motorized lift 200mm |

| Optical path YZ adjustable range | Y=300mmZ=100mm |

| Spot adjustment range | 0.2-2mm |

| Energy fluctuation range | ± 2% |

| Water cooler | 3P |

| Equipment power consumption | 16KW |

| Power Requirement | Three-phase 380V 50Hz/60Hz |

| Cabinet Size | 1500*1000*1500mm |

| Equipment Weight | 300KG |

| Non-standard design | Support non-standard customized solutions |

| Other Options | Suitable for large molds and other boom type solutions |

*REQUIRED FIELDS