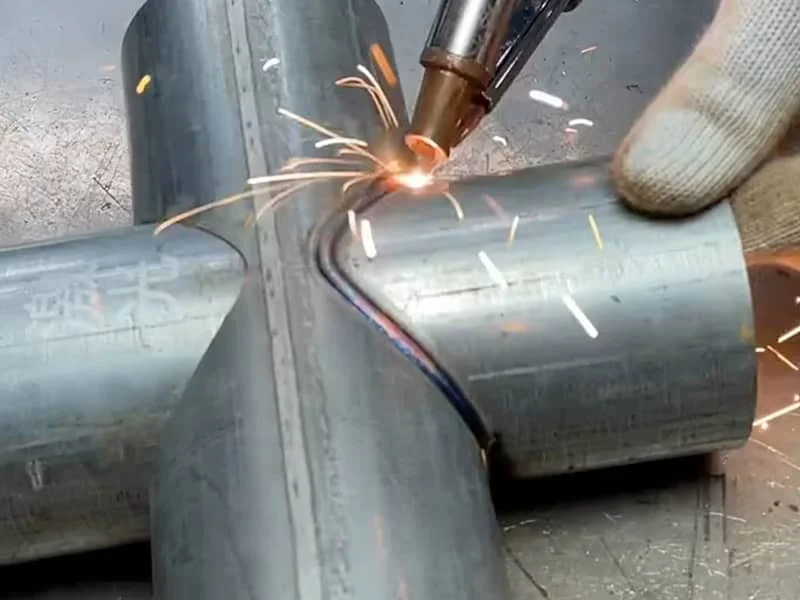

The process of laser welding

Laser welding uses a highly concentrated beam of light on a very tiny spot so that the area under the laser beam absorbs the light and becomes highly energetic. As powerful laser beams are used, the electrons in the area get excited to a point where the material melts as the result of the atoms breaking the bonds with each other.

Which industry relies heavily on laser welding for precision work?

Laser welding applications can be seen in automotive manufacturing, the aerospace industry, medical device fabrication, electronics production, and many more. There are many applications of laser welding due to its ability to provide precise and high-quality welds in a variety of materials, making it a versatile and efficient tool for industries seeking to improve their manufacturing processes.

Automotive Manufacturing

The automotive industry is one of the largest adopters of laser welding technology. Its ability to create precise, high-strength welds makes it indispensable in manufacturing car components.

Aerospace Engineering

Aerospace is another industry where precision and reliability are paramount. Components in aircraft must withstand extreme conditions, requiring welding solutions that ensure durability and flawless execution.

Medical Device Manufacturing

The medical industry demands the highest level of precision and cleanliness in its manufacturing processes. Laser welding is the go-to technology for producing delicate and intricate components.

Electronics and Electrical Equipment

As the world becomes increasingly digitized, the demand for smaller, more precise electronic components continues to grow. Laser welding plays a pivotal role in manufacturing electronics.

General Metal Fabrication

Metal fabrication covers a broad range of applications, from construction to consumer goods. Laser welding is widely used for:

Structural steel components

Metal furniture

Custom metal parts

*REQUIRED FIELDS