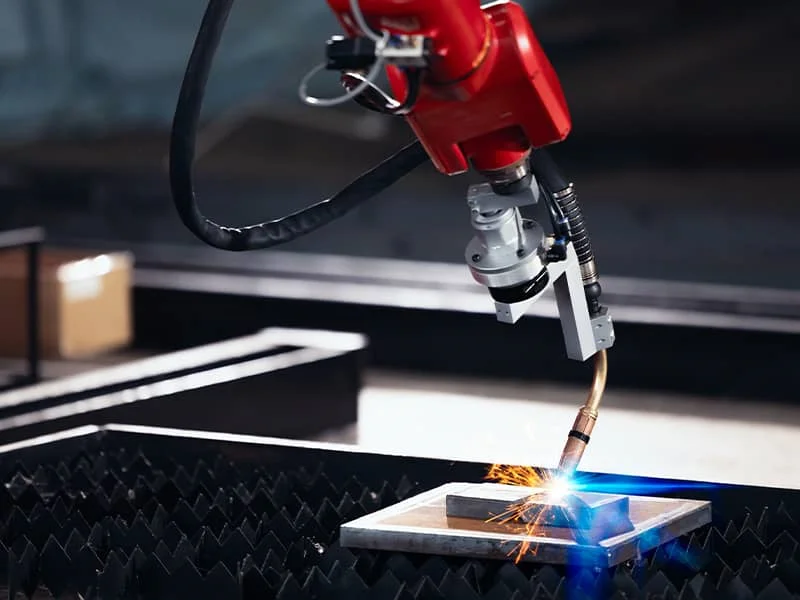

Non-Contact Process

Laser cleaning is a remote process that enables precision material removal, virtually eliminating damage to the underlying material.

Selective Cleaning

Laser cleaning is highly precise and targets only the area to be cleaned, eliminating additional steps like masking.

Safe

Laser cleaning is easily automated and in most cases requires no abrasive materials or chemical solvents, reducing noise and eliminating exposure to hazardous materials.

Sustainable

Laser cleaning is a highly energy efficient process that requires no cleaning media, dramatically reducing material handling requirements and process waste.

Easier, More Flexible Material Removal

The advantages of laser cleaning can benefit a wide variety of industries and processes.

From coatings to contaminants and from flat to complex parts, laser cleaning offers the flexibility and ease of automation to optimize your productivity.

Laser Cleaning Optimizes A Wide Variety of Applications

Clean contaminants like rust, oil, and combustion deposits

Strip coatings like paint, e-coat, ceramics and oxides

Simplify mold maintenance by removing release agents and residuals

Increase bonding by preparing surfaces for welding, bonding, painting, and coating

Increase adhesion with pre-adhesive cleaning or surface texturing

Increase coating life by pre-cleaning before applying part coatings

Sterilize critical equipment in medical and food applications

*REQUIRED FIELDS