Equipped with an adjustable pulse-width fiber laser and an integrated cleaning head, this system offers a wide range of applications. Suitable for surface cleaning of various tool steels, aluminum, copper, stainless steel, beryllium copper, precious metals, and extremely hard materials.

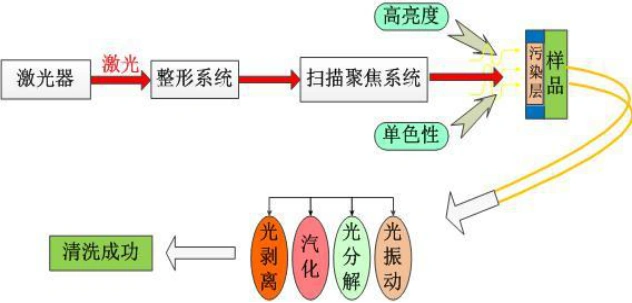

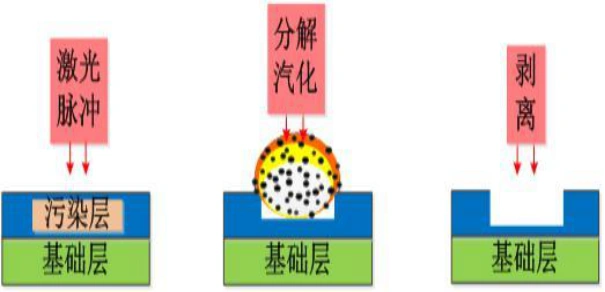

Laser Cleaning Process Mechanism:

a) The laser beam emitted by the laser source is absorbed by the contaminant layer on the surface to be treated.

b) The absorption of high energy rapidly generates a plasma (a highly ionized, unstable gas), which expands abruptly and produces a shockwave.

c) The shockwave fragments the contaminants and removes them from the surface.

d) The laser pulse duration must be sufficiently short to prevent heat accumulation that could damage the underlying substrate.

e) Experiments show that when oxides are present on a metal surface, plasma is generated directly at the metal surface.

Plasma is generated only when the energy density exceeds a certain threshold, which depends on the type of contaminant or oxide layer being removed. This threshold effect is crucial for achieving effective cleaning while ensuring the safety of the substrate material. A second threshold also exists: if the energy density exceeds this higher threshold, the substrate itself will be damaged. Therefore, to enable efficient and safe cleaning, laser parameters must be carefully adjusted so that the energy density of the laser pulses remains strictly between these two thresholds.

Advantages of Laser Cleaning:

Environmentally friendly: Compared to traditional cleaning methods, laser cleaning produces no waste liquids, gases, or other byproducts requiring secondary treatment.

Low operating cost: Requires only a one-time investment with no consumables.

Compact and portable: Ready to use instantly, occupies minimal space, offers high operational flexibility and mobility.

User-friendly: Minimal training required—operators can be qualified after simple instruction.

Minimal substrate damage: Gentle on the base material, preserving its integrity.

● Equipped with an adjustable pulse-width fiber laser and an integrated cleaning head, this system offers a wide range of applications.

● Suitable for surface cleaning of various tool steels, aluminum, copper, stainless steel, beryllium copper, precious metals, and extremely hard materials.

● Compatible with multiple mold steel grades, including S136, NAK80, 718, 738, P20, SKD-11, SKD-61, H13, W302, GS2344, GS2343, GS2082, and other international mold steel specifications.

● Primarily used for cleaning surfaces of aluminum components, copper parts, metal capacitor housings, internal metal EMI shielding meshes in computers, and other types of products.

● Ideal for mold cleaning, oil/grease removal, and rust elimination.

● Widely applied in aerospace, railway equipment, and military hardware for precision surface decontamination.

1.Utilizes a fiber laser with modular design, highly integrated system architecture, maintenance-free operation, and high reliability.

2.Continuously adjustable laser power with excellent beam quality and high stability—making it an ideal laser source for laser cleaning, precision cutting, and fine welding applications.

3.System composition: fiber laser, integrated cleaning head, laser control system, and operator console.

Comes with dedicated laser cleaning software.

4.Adjustable pulse frequency allows customized parameter settings for different material surfaces, ensuring no damage to the substrate while delivering strong adaptability.

5.Supports storage and instant recall of multiple sets of laser parameter profiles for immediate use.

| Condition | Cleaning Method | Background | In Working | Problems | Improvement |

|---|---|---|---|---|---|

| Noise | Abrasive blasting | 75~85dB | – | – | |

| Dry ice | 75~80dB | 100~105dB | High | Earmuffs | |

| Laser | 30~40dB | 60~70dB | – | – | |

| Dust(size) | Dust size | Problems | Improvement | ||

| Abrasive blasting | Big | – | – | ||

| Dry ice | Tiny | Small size dust | It is difficult to collect and a dust mask must be worn | ||

| Laser | Tiny | Small size dust | It can be collected directly with a vacuum cleaner | ||

| Safety | On-Line | Off-Line | Problems | Improbment | |

| Abrasive blasting | – | Good | Off-line cleaning | ||

| Dry ice | Bad | Good | Frostbite from dry ice is a risk. Full protective gear must be worn to prevent both burns and frostbite | Burns can easily occur when cleaning on the machine. | |

| Laser | Bad | Good | Burns can easily occur when cleaning on the machine. | Full protective gear must be worn to prevent burns only. | |

| Model | RL-LMC300H-E |

|---|---|

| Output Power | 100%=300W |

| Wavelength | 1070-1090nm |

| Power Range | 10%-100% |

| Power Stability | ±2% |

| Beam Quality | 1.3(20μ-QBH) |

| Pulse width | 2-500ns |

| Frequency | 1-4000KHz |

| Welding Depth | ≤0.5mm (Depends on material) |

| Laser scanning range | 100mm/70mm |

| Cooling | Air |

| Scanning Head | Wobble Scanning Head |

| Power Consumption | Max 2KW |

| Electrical Connection | 220V/50Hz |

*REQUIRED FIELDS