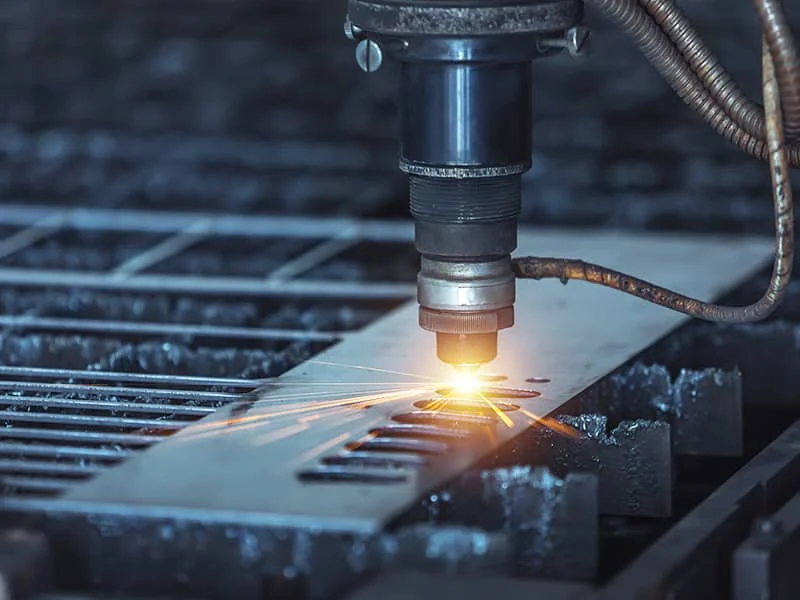

For all battery cell technologies, whether cylindrical, prismatic, or pouch, conductive busbars are used to connect individual cells into modules. Laser welding enables the creation of busbar-to-cell connections that meet critically important electrical performance requirements while also offering unmatched production speed, reliability, and ease of automation.

The Fastest Module Busbar Welding

Laser welding is capable of making more busbar-to-terminal welds per second than any other metal joining process, enabling manufacturers to dramatically increase module throughput.

Ultra-Consistent Welding Results

Laser welding is a non-degrading, non-contact process that produces consistent, high-quality welds across millions of busbar-to-terminal connections.

Highly Flexible Weld Joint Design

Laser parameters can be easily adjusted to match changing module production requirements such as weld size, shape, and pattern with no mechanical changes required.

*REQUIRED FIELDS