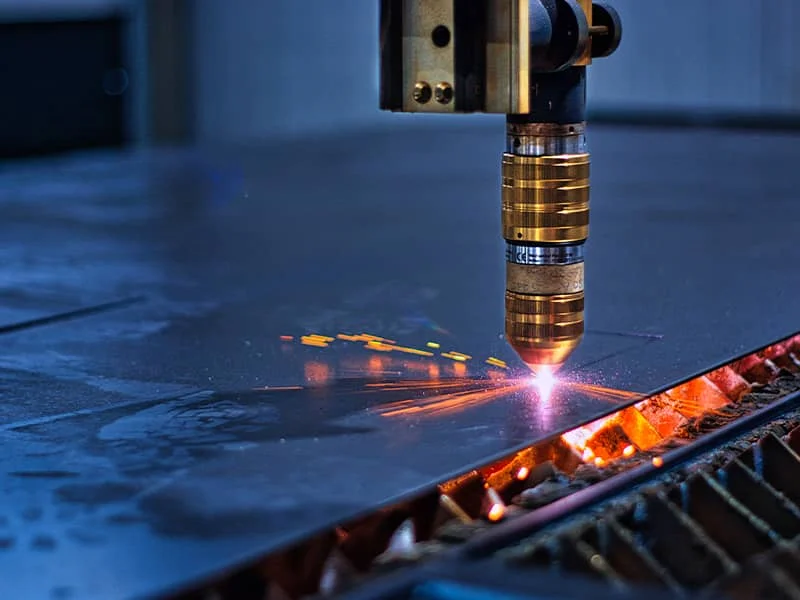

Despite the variety in designs, the cylindrical, prismatic, and pouch cell manufacturing process consistently leans on laser processing for crucial tasks such as cutting and notching foils, welding foil stacks to tabs, sealing injection holes in cell cases, welding safety valves, and sealing caps to cases. Complemented by cutting-edge advancements like laser drying of electrode coatings, these processes ensure the swift pace and efficiency necessary for high volume production of Li-ion cells.

Ultra-Efficient Electrode Foil Drying

We see ourselves as more than a developer of innovative laser systems. It’s also important to offer service close to the customer and custom advice – from the design of a needs-based solution to professional implementation on site to reliable support. We offer you substantial warranty services and professional training. You can trust in investment and planning security as well as smooth production processes from the beginning onward.

All this is included in our service. We give advice on equal terms, and show complete commitment to fulfil our customers’ wishes. Only true partnership offers you outstanding added value.

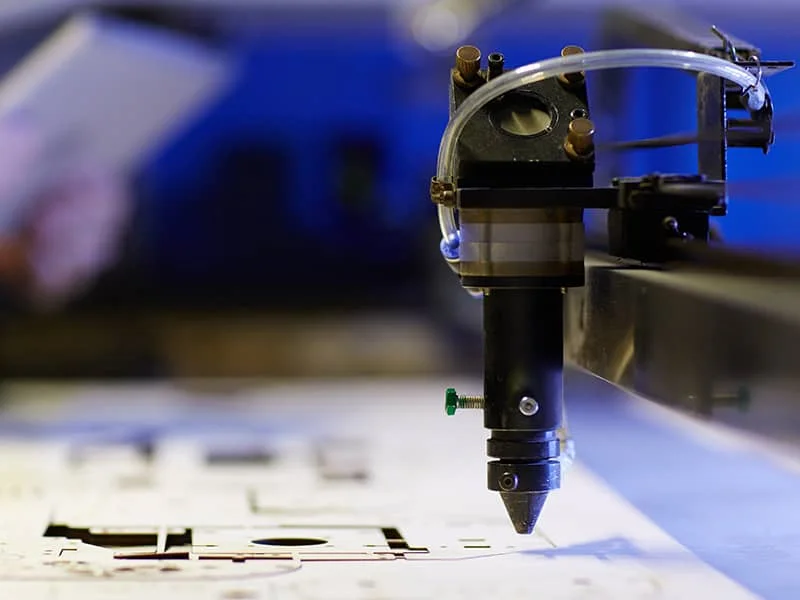

Repeatable, High-Quality Electrode Foil Cutting

Laser cutting, also known as laser slitting, is a non-contact process that has the flexibility to cut foils of any shape and is not susceptible to foil edge quality degradations due to die punching tool wear. Using the most reliable nanosecond pulsed lasers in the industry, IPG laser solutions deliver the fastest foil cutting with the highest cut quality.

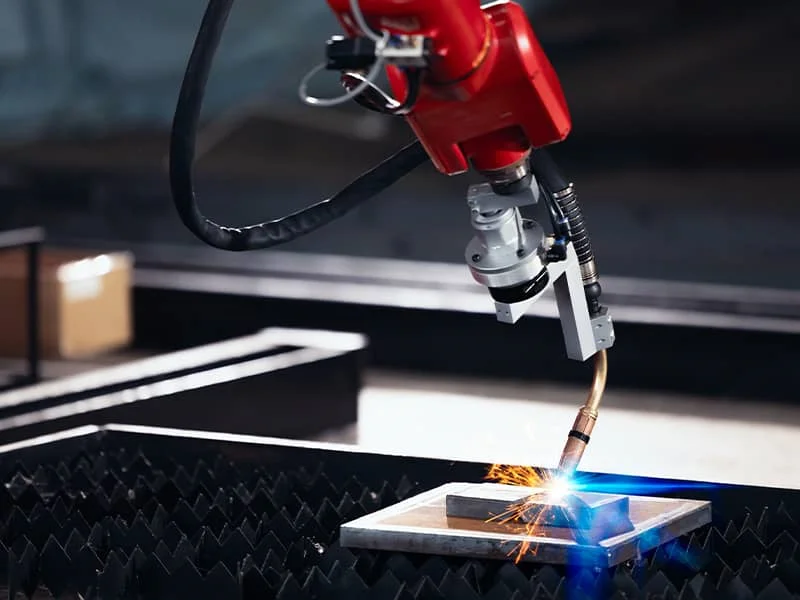

High Yield Foil-to-Tab Welding

Compared to alternate technologies where excess mechanical force can create metal fractures, laser welding is a fast, non-contact joining process with consistently high yields. Dual-beam laser welding technology greatly minimizes copper and aluminum welding defects at significantly higher speeds than green or blue wavelength laser alternatives.

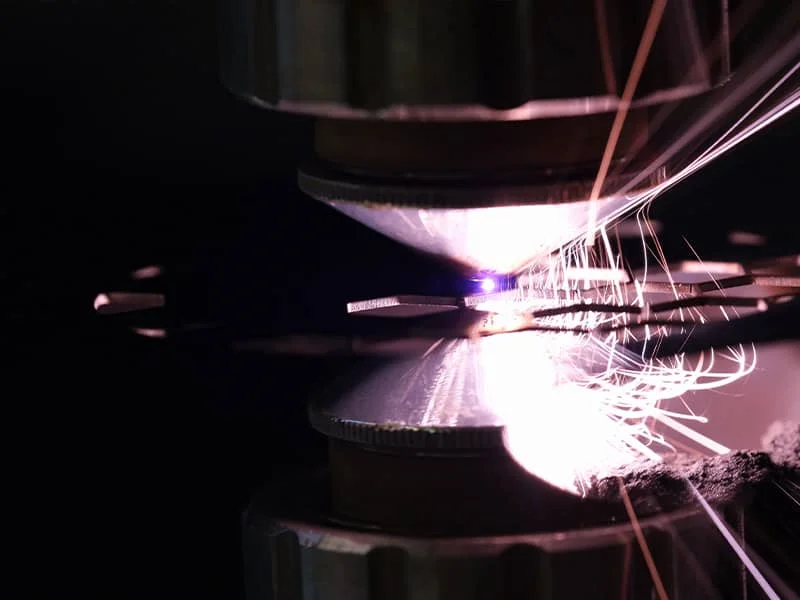

High Throughput Cap-to-Can Welding

Dual-beam lasers create hermetic cap-to-can welds at the high welding speeds that are necessary for large-format prismatic or blade batteries. IPG offers the widest selection of dual-beam laser configurations, enabling real-time dynamic power control of the core and ring beams to perfectly match cell enclosure seal requirements.

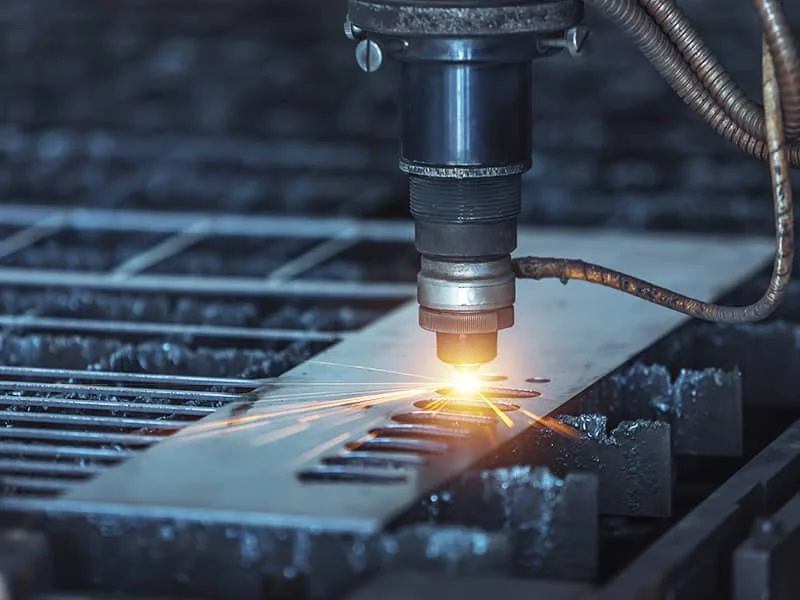

Faster, More Reliable Injection Hole Sealing

Quasi-Continuous Wave lasers minimize heat input using bursts of high peak power to create high-quality injection hole seals at high speeds and use a highly reliable, air-cooled solid state fiber laser design that greatly increases tool uptime.

*REQUIRED FIELDS