Precise & Repeatable

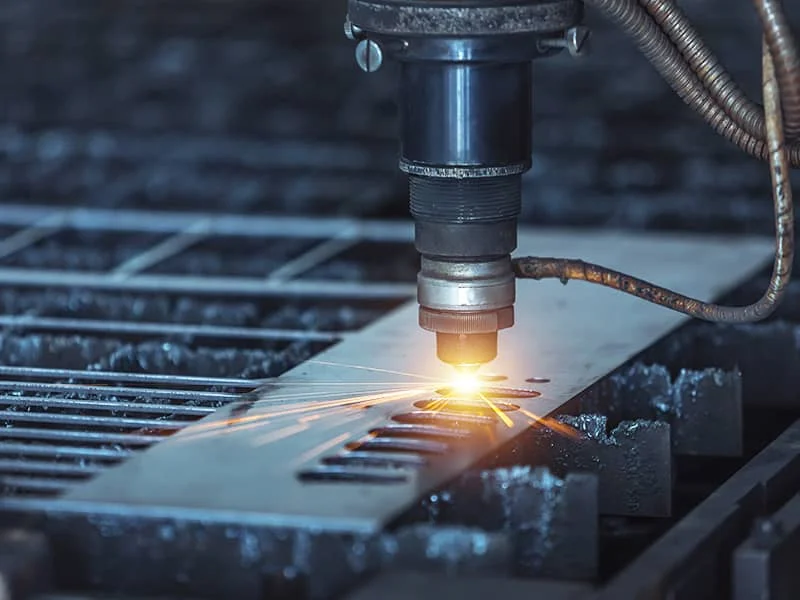

Laser cutting is a highly precise and consistent process able to reliably create excellent quality cutting edges and complicated part features.

High Process Speed

Focused laser beams rapidly penetrate thick and thin materials and can be rapidly translated along the intended cutting edge to achieve high cutting speeds.

Minimal Maintenace Required

Laser cutting is a non-contact process that experiences virtually no degradation in cutting quality, minimizing laser cutting systems downtime.

Flexible & Easily Automated

As a non-contact process, laser cutting can be easily integrated into a wide variety of systems ways and used to cut almost any material or feature.

Flexible Cutting for a Variety of Materials & Features

Whether for thick or thin materials, precision features on complex surfaces, or reflective metals, laser cutting offers high process speeds and edge quality.

Laser cutting productivity and quality can be maximized for nearly any application by customizing laser parameters like wavelength, power, spot size, and pulse duration.

The power and flexibility of laser cutting makes maximizing productivity with automated solutions viable for almost any business.

Laser cutting scan be seamlessly integrated with a variety of supporting systems including optimized process gas delivery and process monitoring like pierce detection.

*REQUIRED FIELDS