Laser cutting is used to optimize processes, applications, and production across a wide range of industries including electronic, automotive, medical, metalworking, woodworking, printing, packaging, HVAC and other specialty industries.

When you need just-in-time manufacturing, laser technology is the ideal converting solution. Machines with this capability increase the accuracy of your overall production by ensuring clean lines and precise detailing on your finished products.

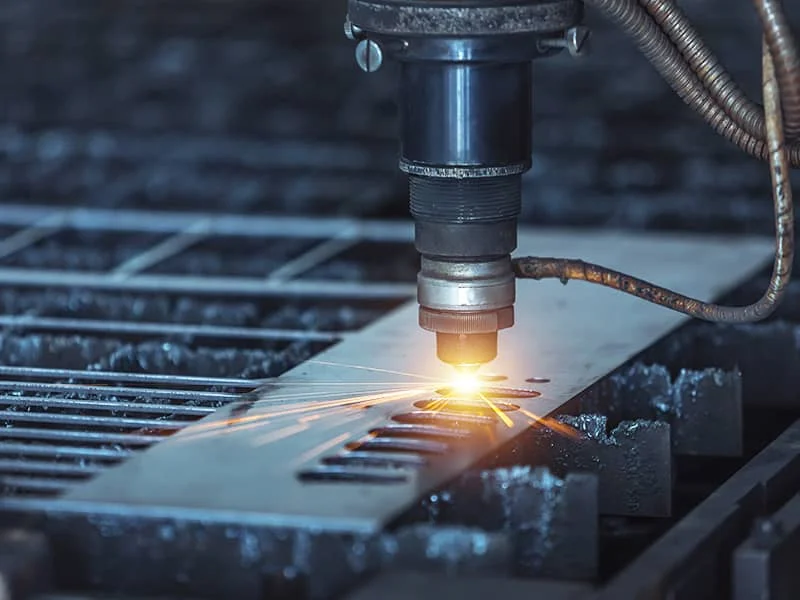

How Laser Cutting Works

Laser cutting directs the output of a high-power laser through optics to cut and engrave materials into programmable designs and dimensions. Precision laser cutting can be used to produce through holes, slots, and diameters that are significantly smaller (and at tighter tolerances) than results generated by other converting processes. It is a dieless process, meaning no hard tools are needed, eliminating expensive and time-consuming die costs.

As it makes its way across the material, the laser vaporizes material in the beam path, leaving an edge with a high-quality surface finish, eliminating the need for complex extraction methods to remove scrap and smaller pieces usually left behind by other cutting machine. This method of material modification allows you to quickly change designs while also improving the quality of finished parts.

Advantages of Your Business Investing in a Laser Cutter

● 100% Savings in Tooling Costs

● 40% Increase in Material Yields

● 40% Reduction in Job Changeovers

● Increased Flexibility in Designs

● Increased Precision Levels & Edge Quality

● Increased Depth of Cut Control

● Total Cut, Kisscut & Engrave on Same Layout

● Increased Productivity on Short and Long Runs

● Ease of Use and Increased Throughput

*REQUIRED FIELDS