Adopting single mode fiber continuous laser, QBH handheld welding head has a wide range of applications. Mainly used for a variety of sheet metal welding, assembly welding of processed parts, etc.. Suitable materials: stainless steel, carbon steel, aluminum alloy, etc.

● Adopting single mode fiber continuous laser, QBH handheld welding head has a wide range of applications.

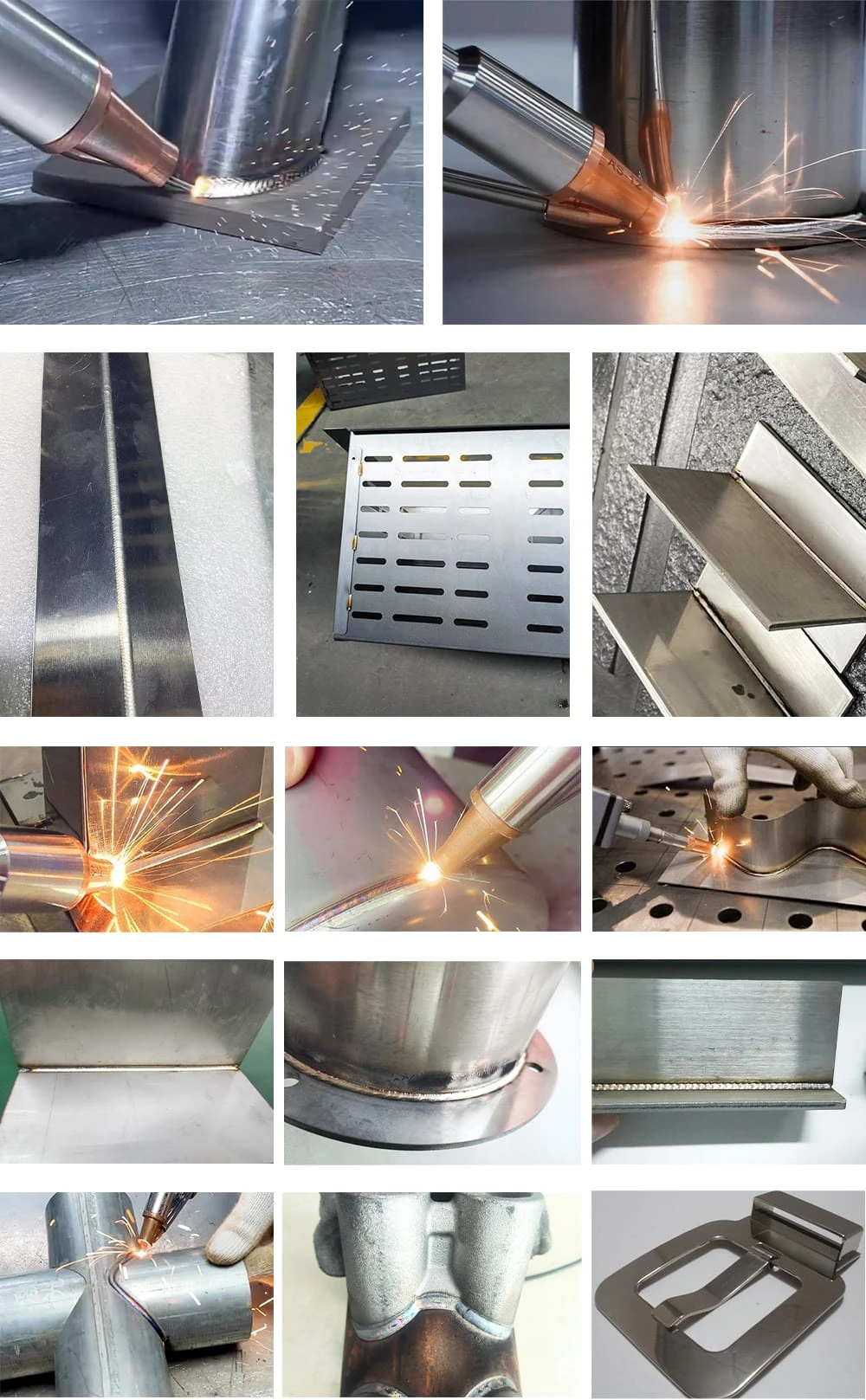

● Mainly used for a variety of sheet metal welding, assembly welding of processed parts, etc.. Suitable materials: stainless steel, carbon steel, aluminum alloy, etc.

● Compared with traditional welding, it has the following advantages 1. small thermal deformation 2. high efficiency 3. high appearance quality

● The handheld welding head is flexible and convenient, and can realize outdoor welding;

● High welding efficiency, 2-10 times faster than traditional welding;

● The operation mode of the handheld welding torch enables the workpiece to be welded at any position and at any angle;

● Suitable for spot welding of various complex welding joints and various equipment;

● Compared with traditional welding, the weld is smooth and beautiful, with few defects, deeper welding depth, and smaller thermal stress deformation.

Comparison between ordinary welding joint and swing welding joint

● The oscillating head can obtain a wider weld seam than the ordinary head, which can reduce the requirements for workers' skills in hand-held welding.

● The swing head adopts a high-speed rotation mechanism, which can stir materials and achieve the effect of stir welding. It can be compatible with larger gaps than ordinary heads.

Welded aluminum alloy swing heads have incomparable advantages over ordinary heads

The ordinary head is compatible with gaps smaller than 1/5 of the thickness of the material to be welded.

The swing head is compatible with gaps smaller than 1/3 of the thickness of the material to be welded.

It is widely used in cabinets, kitchens and bathrooms, stair elevators, stainless steel home and other hardware industries, and can perfectly replace traditional hydrogen arc welding.

| Equipment Model | RL-LF3000H-D-G |

|---|---|

| Output power | Max 3000W (continuously adjustable), other options 1500W, 2000W |

| Laser wavelength | 1060-1070nm |

| Power Stability | ±2% |

| Beam quality M2 | 1.5(100μ-QBH) |

| Cooling method | Water-cooled |

| Modulation frequency | 50KHz |

| Welding depth | ≤6mm (depending on material) |

| Wire feeder | Double wire feeder |

| Welding wire size | 0.8-2.4mm |

| Wire feeding tube | Graphite/General |

| Control mode | Plate |

| Environmental Requirements | Temperature: 0℃~50℃ /Humidity: 5%~80% |

| Spot Adjustable Range | 0.1-5mm |

| Spot Pattern | Various |

| Welding head type | QBH single swing |

| Standard External Dimensions | 800*700*600mm |

| Power Requirements | Three-phase 380V 50Hz/60Hz |

| Equipment Power Consumption | 12KW |

| Equipment Body Color | White/Gray |

| Equipment Weight | 100KG |

| Non-standard design | Support non-standard customized solutions |

*REQUIRED FIELDS