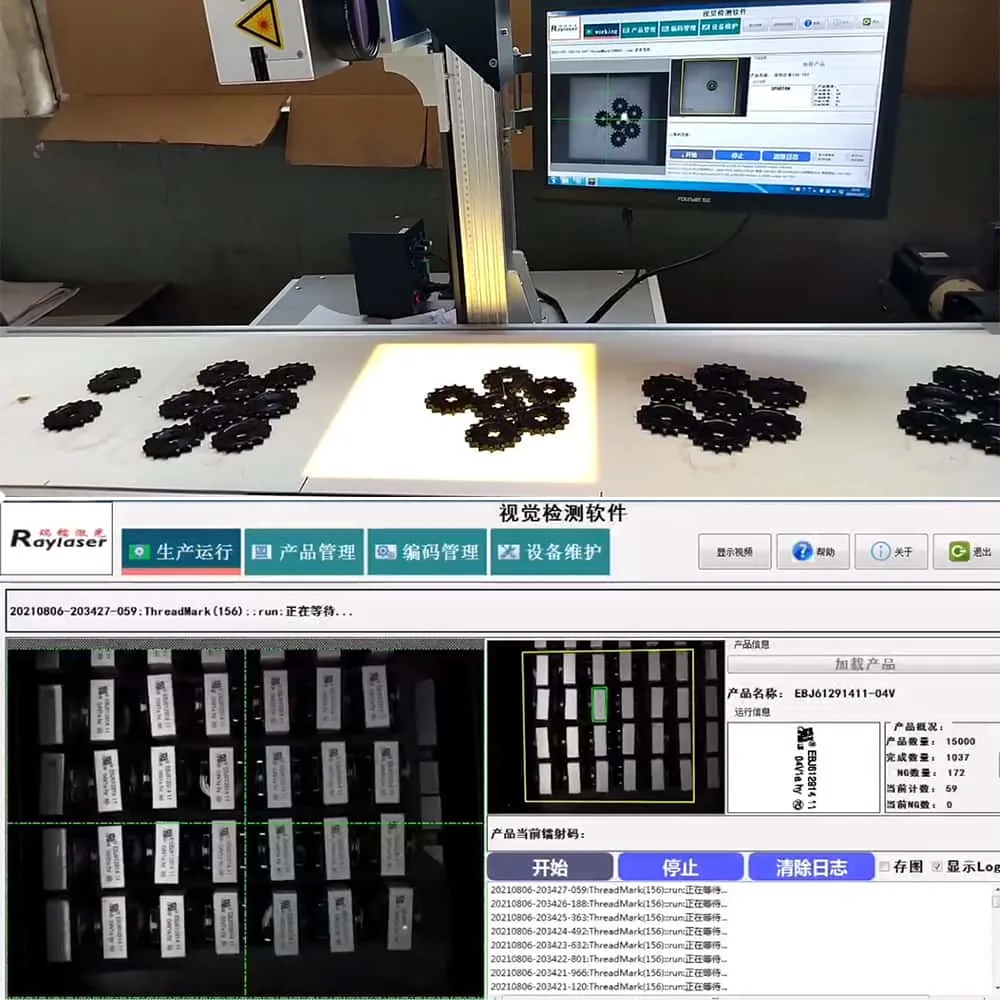

One-touch auto-calibration to correlate laser and vision coordinates. One-key aberration correction, suitable for high-precision occasions, to correct the vision lens. Adaptive auto-positioning mode, only need to draw a frame to realize auto-positioning function, single multiple products marking.

● One-touch auto-calibration to correlate laser and vision coordinates.

● One-key aberration correction, suitable for high-precision occasions, to correct the vision lens.

● Adaptive auto-positioning mode, only need to draw a frame to realize auto-positioning function, single multiple products marking.

● Marking information can be fixed or changed (support communication access, ASCI/conversion, binary and hexadecimal modes).

● Multi-template product management, easy to switch between different products, chart file following mode.

● Camera imaging field of view is large, applicable to any plane product marking.

● Product any angle, any number, the camera automatically recognizes the product marking.

| Equipment Model | RL-VP-G |

|---|---|

| Power Requirement | 220V 13A |

| Output Power | Fiber: 20W/30W/50W/100W/200W/300W Ultraviolet: 5W/12W/20W |

| Laser wavelength | 1064nm/355nm/532nm |

| Engraving depth | 0.01mm-0.5mm (continuously adjustable) |

| Marking range | Maximum support 70mm×70mm Effective range: 30mm*30mm |

| Minimum line width | 0.02mm@f160 |

| Minimum character | 0.1mm |

| Maximum Marking Speed | 7000mm/s |

| Laser Repeat Positioning Accuracy | 0.008mm |

| Camera Pixel | 5 million/12 million/20 million |

| Visual guidance positioning accuracy | 0.1-0.15mm (combined) Precision design program accuracy up to 0.02mm |

| Number of motion axes | Supports 4-axis motion |

| Pulse frequency | 20~100KHz |

| Cooling method | Air-cooled |

| Environmental requirements | Temperature: 0℃~50℃ /Humidity: 5%~80 |

| Equipment power consumption | 1KW |

| Electricity Requirement | 220V /50Hz |

| Equipment weight | 70KG |

*REQUIRED FIELDS