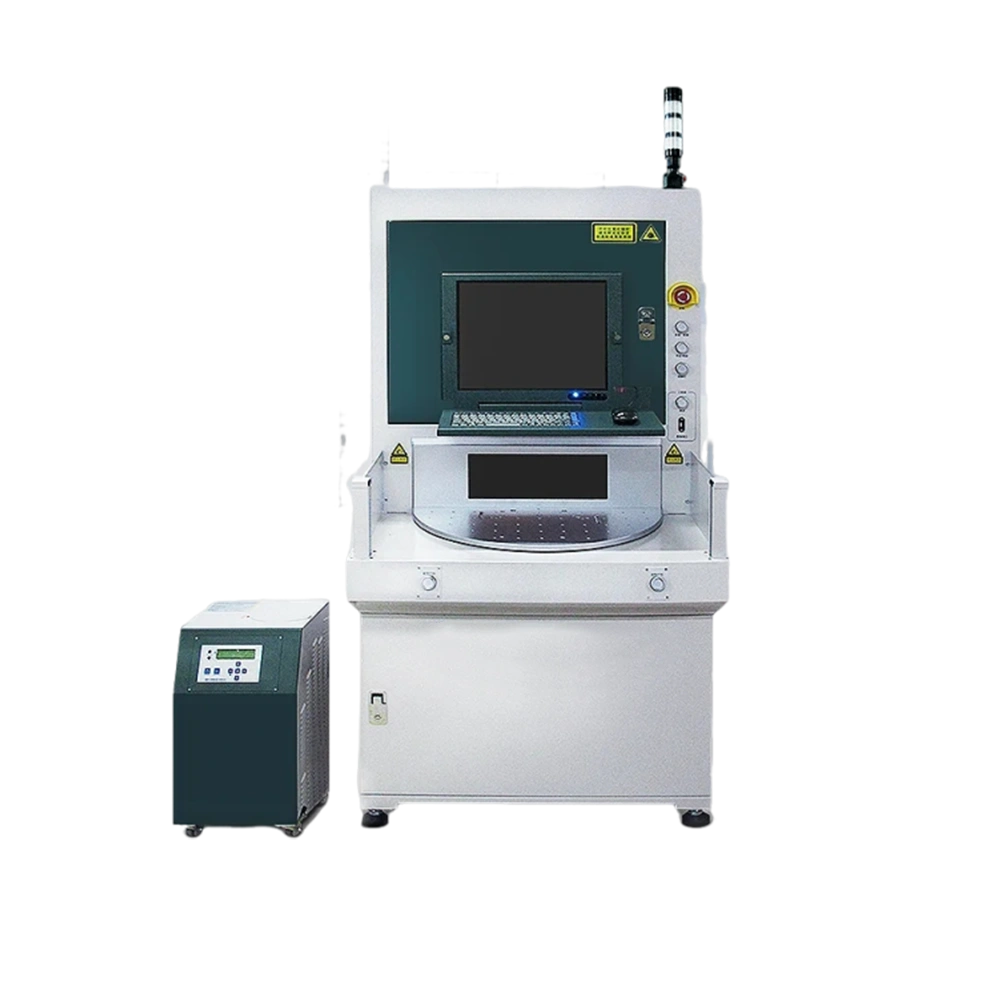

What are the application fields of laser welding machines?

Laser welding machine, also called laser welding machine and laser welding machine, is a commonly used equipment for material processing and welding. It is a new type of welding method. The use of laser welding machine can realize welding, butt welding, stack welding, sealing welding, etc. The overall welding speed is fast, and the weld seam is smooth and beautiful. Let’s follow Huiyao’s editor to learn about the application fields of laser welding machines.

1. Battery industry

In the power battery production process, from cell manufacturing to PACK assembly, welding is an important manufacturing process. In particular, the power battery structure contains a variety of materials, such as steel, aluminum, copper, nickel, etc. These metals can be made into electrodes, wires or casings. Whether it is welding between one material or multiple materials, laser welding can effectively utilize the excellent directionality and high power density of the laser beam to work. The advantages of laser welding have been fully utilized in the battery industry.

2. Automobile manufacturing industry

Laser welding machine is non-contact processing, has no pollution to the product, is fast, and is more suitable for the production process requirements of high-end automotive consumer products. Cars made of laser welded aluminum alloy are formed by laser welding thin aluminum alloy, which not only greatly reduces the weight of the car body, but also reduces the process of manufacturing cars and improves production efficiency. It is welcomed by the majority of car manufacturers.

3. Electronic and electrical industry

Due to the small heat-affected zone, rapid heating concentration and low thermal stress of laser welding, it shows unique advantages in the packaging of integrated circuits and semiconductor device casings.

In the development of vacuum equipment, laser welding has also been applied. The thickness of elastic thin-walled corrugated plates in sensors or thermostats is 0.05-0.1mm, which is difficult to solve with traditional welding methods. TIG welding is easy to penetrate, but the plasma stability is not good, and there are many influencing factors. Laser welding has very good results. It is widely used.

4. Jewelry industry

Due to the high precision of laser processing, it is very suitable for precious small products in the jewelry industry. Because the laser focused beam is extremely thin, it can be magnified by a microscope to enlarge the small parts of the jewelry to achieve precision welding. The connection of jewelry chains and the inlay of gemstones need to be completed with a laser spot welding machine. Laser spot welding machine is a must-have equipment.

5. Home building materials industry

Laser welding precision has good appearance, so it is widely used in laser marking and laser welding of bathroom stainless steel products. For example: handles, water, stainless steel tableware, knives, etc. are often laser marked to produce corporate LOGOs, and seals such as electric kettles are also completed using laser welding.

6. Mold and machinery manufacturing industry

A typical example of the application of laser welding in the mold industry is the mold repair laser welding machine. Due to the obvious advantages of non-contact processing, laser processing is particularly suitable for mold and high-precision machinery manufacturing industries due to its fineness and small impact on materials, such as plastic molds, rubber molds, stamping molds, casting molds, etc., as well as forging molds. , precision repair of drawing molds.

+86 18663958101

+86 18663958101