What materials are laser welding machines suitable for welding? What needs to be paid attention to?

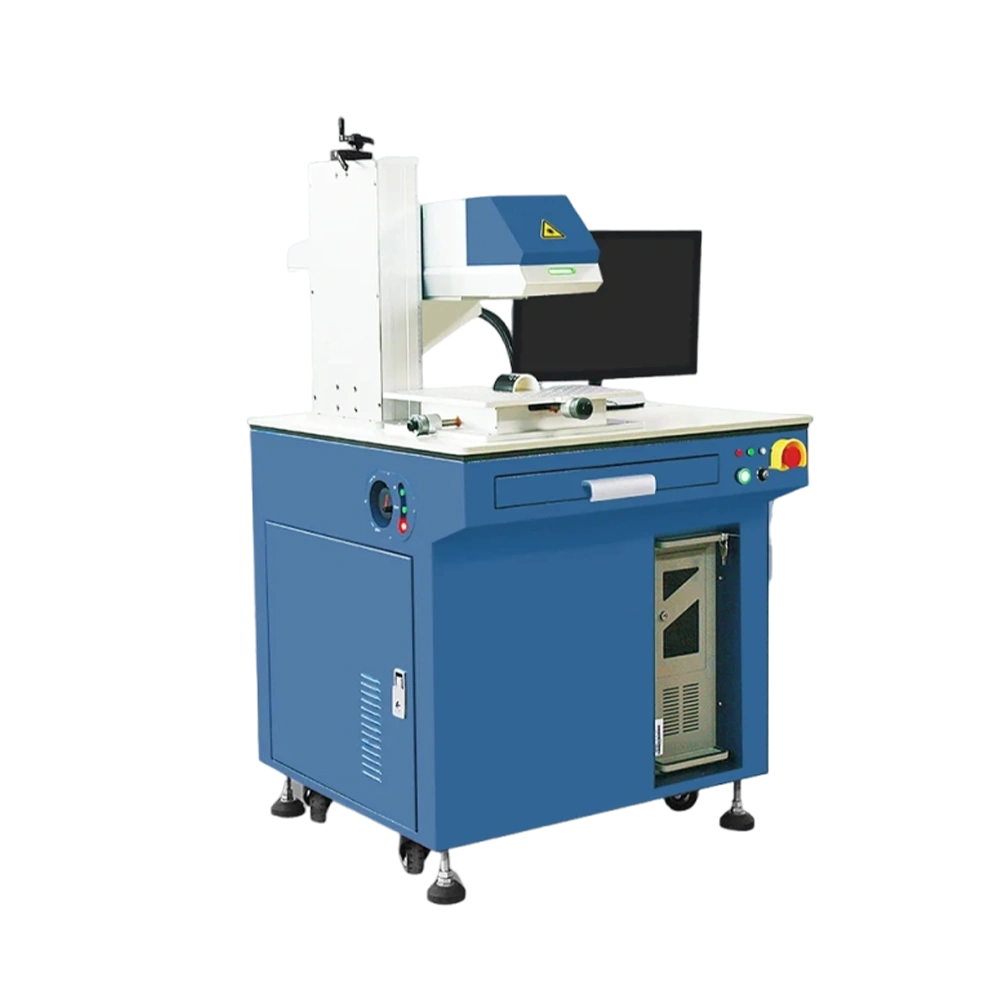

I believe everyone is familiar with laser welding machines. It is a machine used for laser material processing. It is an emerging industry technology in industrial welding processing and is widely used. At the same time, the laser welding machine's high-precision, high energy efficiency, non-destructive, and non-contact welding technology is suitable for welding many materials, but there are still many people who don't know what materials the laser welding machine is suitable for welding. The editor will introduce it to you in detail below.

What materials are laser welding machines suitable for welding?

1. Metal materials: Laser welding machines are suitable for welding metal materials, such as stainless steel, aluminum, copper, titanium alloy, nickel alloy, iron, steel, etc.

2. Plastic materials: Laser welding machines can also be used to weld certain plastic materials, such as polycarbonate (PC), polypropylene (PP), polyurethane (PU), etc.

3. Carbide: Laser welding machines can also be used to weld cemented carbide, such as knives, blades, molds, etc.

4. Other materials: glass, graphite, etc.

Precautions for welding materials of laser welding machine

1. Material selection: Different materials have different optical properties and thermal conductivity characteristics, so laser welding parameters need to be selected for specific materials.

2. Surface treatment: The surface of the workpiece needs to be cleaned and polished before welding to ensure that there are no oxides or other contaminants at the welded joint.

3. Welding parameter settings: Different materials require different welding parameters when welding, including laser power, spot diameter, welding speed, etc. If set up incorrectly, poor weld quality or material damage may result.

4. Welding process control: Laser welding is a high-precision, high-speed welding technology, so it requires fine control of the welding process, including welding speed, laser power, spot shape and position, etc.

5. Welding safety: Laser welding produces high-energy-density laser beams, and safety issues need to be paid attention to. For example, workers must wear protective glasses, protective gloves and other protective equipment.

6. Quality inspection: After welding is completed, quality inspection is required, such as the strength, appearance quality, pores, cracks, etc. of the weld.

+86 18663958101

+86 18663958101