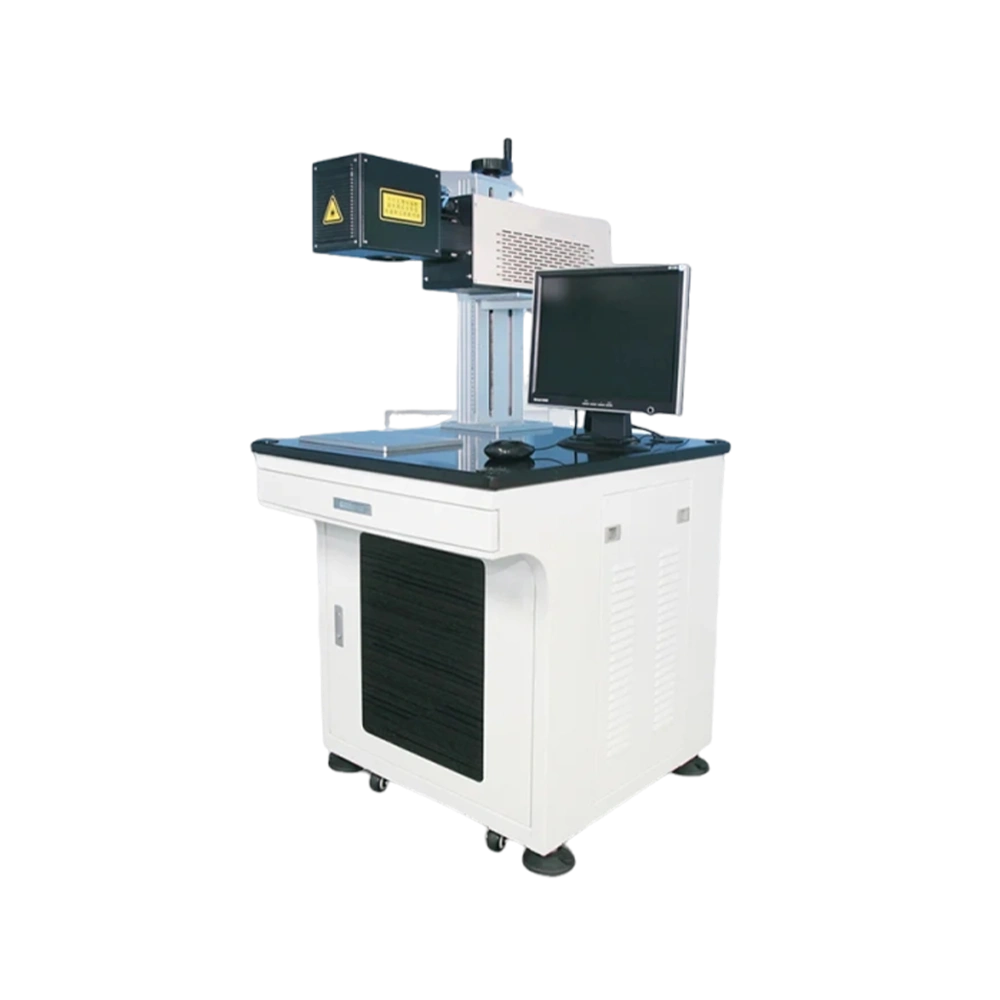

What are the common abnormal problems and solutions for laser welding machines?

Laser processing has now been rapidly applied in various industries, especially the applications of metal laser cutting and welding, which have long been familiar to people. Laser welding is a new type of welding method. It is mainly aimed at welding thin-walled materials and precision parts. It can realize spot welding, butt welding, stack welding, seal welding, etc. It has a high aspect ratio, small weld width, and small heat-affected zone. , small deformation, fast welding speed, smooth and beautiful welds, no processing required or only simple processing after welding, high weld quality, no pores, precise control, small focused light spot, high positioning accuracy, easy to realize automation. Therefore, when using a laser welding machine, some malfunctions may occur, which affects the working efficiency of the laser welding machine. So what are the common problems with laser welding machines ? What are the specific solutions?

Problem 1. Cracks appear during laser welding machine welding

Cause analysis and solutions: Keep the workpiece clean; when the workpiece fitting gap is too large or has burrs, the processing accuracy of the workpiece should be improved; the cooling speed of the workpiece is too fast, and the temperature of the cooling water should be adjusted on the fixture to increase the water concentration. Temperature; the flow rate of the protective gas is too large, which can be solved by reducing the flow rate of the protective gas.

Problem 2. The laser welding machine has insufficient welding penetration.

Cause analysis and solutions: Lack of laser energy can improve pulse width and current; the focus lens is not the correct amount, and the focus amount and proximity to the focus position should be adjusted.

Problem 3. The weld seam is very dark when the laser welding machine is welding.

Cause analysis and solution: The air flow direction of the protective gas is incorrect. The air flow direction of the protective gas should be opposite to the direction of the workpiece.

Problem 4. The flame of the laser welding machine weakens during welding

Cause analysis and solutions: The focusing lens or laser resonator film is damaged or contaminated and should be replaced or cleaned in time; the laser does not output from the center of the copper nozzle under the focusing head. Adjust the 45° reflection diaphragm so that the laser outputs from the center of the nozzle; Main optical path laser deviation, main optical path total reflection and semi-reflection diaphragm adjustment, image paper inspection, dot adjustment; cooling water contamination or cooling water not replaced for a long time can be solved by replacing the cooling water and cleaning the ultraviolet glass tube and xenon lamp.

+86 18663958101

+86 18663958101