Laser Welding of Stainless Steel Tubes

In recent years, due to growing environmental concerns, automakers have come under increasing pressure to improve fuel efficiency. Tighter and more restrictive regulations have posed technical challenges to industrial production and material processing. These trends include reduced emissions, lighter vehicles, and extended component life.

Advances in material processing have created unique opportunities for stainless steel tube production. Specifically, manufacturers are being asked to produce parts that are lighter in weight while still offering corrosion resistance and meeting strength requirements. Furthermore, space constraints within vehicle bodies have placed a greater emphasis on formability. Typical applications include exhaust pipes, fuel lines, fuel injectors, and other components.

In the production of stainless steel tubes, flat steel strips are first formed and then shaped into a round tube. Once formed, the seams of the tubes must be welded together. This weld significantly impacts the part's formability. Therefore, selecting the appropriate welding technology is crucial to achieving welded profiles that meet the rigorous testing requirements of the manufacturing industry. Undoubtedly, gas tungsten arc welding (GTAW), high-frequency (HF) welding, and laser welding have each found their place in the manufacture of stainless steel pipe.

High-frequency induction welding

In both HF contact welding and HF induction welding, the current supply and the pressure supply are separate. Furthermore, both methods utilize magnetic rods—soft magnetic elements placed inside the pipe to help focus the weld flow at the edges of the strip. In both cases, the strip is cut and cleaned, then coiled and brought to the welding point. Furthermore, coolant is used to cool the induction coils used during the heating process. Finally, some coolant is used during the extrusion process. Here, high forces are applied to the extrusion pulleys to avoid porosity in the weld area; however, the increased pressure results in increased burrs (or weld beads). Therefore, specially designed tools are used to remove burrs from both the inside and outside of the pipe.

One of the main advantages of the HF welding process is its ability to process steel pipes at high speeds. However, as is typical in most solid-state welding processes, high-frequency welded joints are difficult to reliably test using traditional non-destructive techniques (NDT). Weld cracks can occur in thin, flat areas of low-strength joints, making them undetectable using traditional methods and potentially unreliable in demanding automotive applications. Gas Tungsten Arc Welding (GTAW) Traditionally, steel pipe manufacturers have chosen gas tungsten arc welding (GTAW) as their welding process. GTAW generates an arc between two non-consumable tungsten electrodes. Simultaneously, an inert shielding gas is introduced from a torch to shield the electrodes, generate an ionized plasma stream, and protect the molten weld pool. This is an established and well-understood process that produces repeatable, high-quality welds. The advantages of this process include repeatability, spatter-free welding, and the elimination of porosity. GTAW is considered an electrically conductive process, so it's relatively slow. High-Frequency Arc Pulsing In recent years, GTAW welding power sources, also known as high-speed switching, have enabled arc pulses exceeding 10,000 Hz. Pipe fabricators have been the first to benefit from this new technology. High-frequency arc pulses result in a downward arc pressure five times greater than with conventional GTAW. Typical improvements include increased blast strength, faster welding speeds, and reduced scrap. Pipe fabricators quickly discovered that this process required a smaller weld profile. Furthermore, welding speeds are still relatively slow.

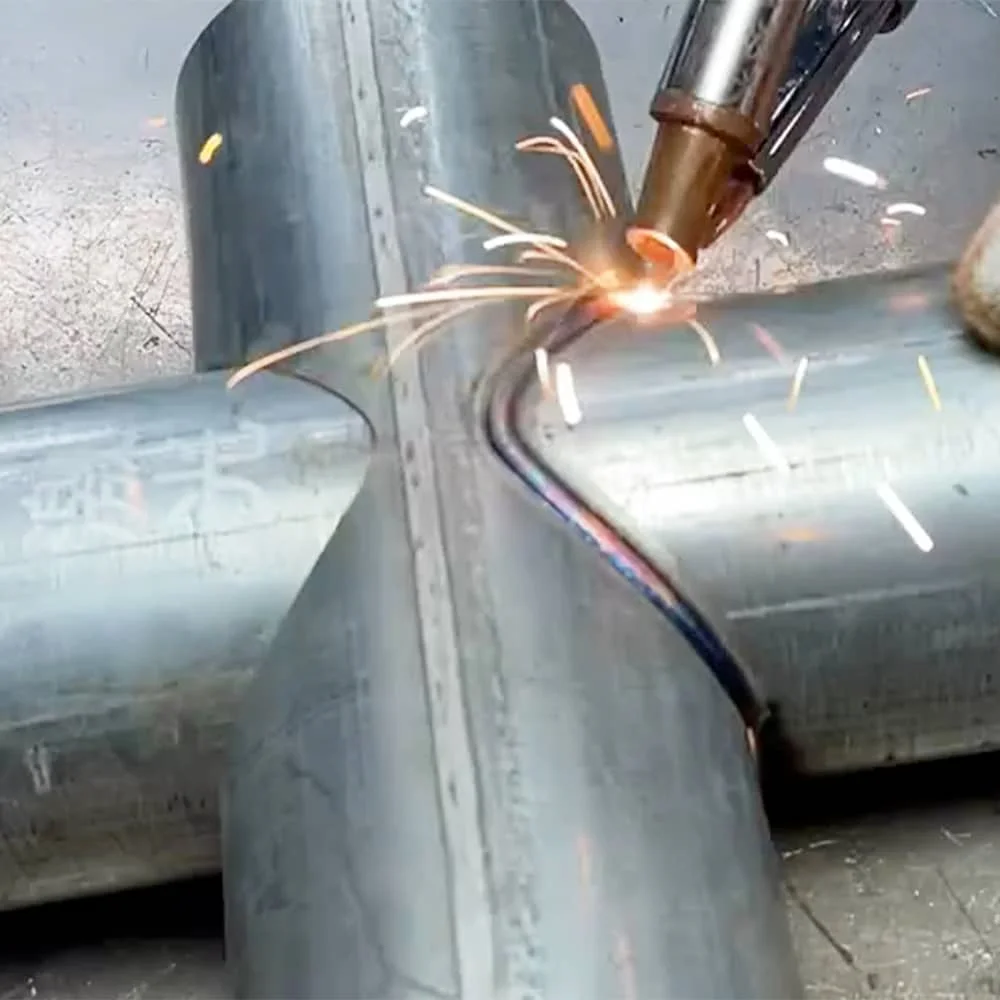

Laser Welding In all pipe welding applications, the edges of the steel strip are melted and then solidified as the edges are pressed together using a clamping fixture. However, a unique characteristic of laser welding is its high beam energy density. The laser beam not only melts the surface layer of the material but also creates a keyhole, resulting in a very narrow weld profile. Power densities below 1 MW/cm² For processes like GTAW, the energy density is insufficient to create a keyhole. Consequently, keyless processes produce wide and shallow welds. The high precision of laser welding results in more efficient penetration, which in turn reduces grain growth and improves metallographic quality. On the other hand, GTAW's higher heat input and slower cooling process result in a rougher weld structure.

Generally speaking, laser welding is considered faster than GTAW. While they offer similar scrap rates, laser welding offers improved metallographic properties, resulting in higher burst strength and greater formability. Compared to high-frequency welding, laser processing eliminates material oxidation, leading to lower scrap rates and improved formability.

The Impact of Spot Size

In stainless steel pipe welding, weld depth is determined by pipe thickness. Consequently, the production goal is to improve formability by reducing weld width while achieving higher speeds. When selecting the most suitable laser, beam quality must not be the only consideration; the accuracy of the pipe mill must also be considered. Furthermore, before the dimensional tolerances of the tube mill can be considered, the limitations of spot reduction must be considered. There are many dimensional issues specific to steel pipe welding, but the primary factor affecting welding is the seam at the weld box (more specifically, the weld coil). Once the strip is formed and prepared for welding, weld characteristics include: gaps between the strips, significant/minor weld misalignment, and variations in the weld centerline. The gap determines how much material is needed to form the weld pool. Excessive pressure will result in excess material at the top or inside diameter of the pipe. On the other hand, significant or minor weld misalignment will result in poor weld appearance.

Furthermore, after the weld box, the pipe undergoes further finishing. This includes both dimensional and shape adjustments. While additional work can remove some significant/minor weld defects, it may not eliminate them all. Of course, zero defects are desirable. Generally, a rule of thumb is to limit weld defects to no more than 5 percent of the material thickness. Exceeding this value will compromise the strength of the welded product.

Finally, the presence of a weld centerline is crucial for the production of high-quality stainless steel pipe. The automotive market's increasing emphasis on formability directly correlates to the need for a smaller heat-affected zone (HAZ) and smaller weld profiles. This, in turn, is driving the development of laser technology, specifically improving beam quality to reduce spot size. As spot size continues to shrink, increasing focus is placed on the accuracy of scanning the seam centerline. Generally, steel pipe manufacturers strive to minimize this deviation, but in practice, achieving an accuracy of 0.2 mm (0.008 in) is difficult. This has led to the need for seam tracking systems. The two most common tracking technologies are mechanical scanning and laser scanning. Mechanical systems, on the one hand, use a probe to contact the seam upstream of the weld pool, which is subject to dust, wear, and vibration. These systems have an accuracy of 0.25 mm (0.01 in), which is insufficient for high-beam-quality laser welding. Laser seam tracking, on the other hand, can achieve the required accuracy. Typically, a laser beam or spot is projected onto the weld surface, and the resulting image is fed to a CMOS camera, which uses algorithms to determine the location of the weld seam, misjoints, and gaps. While imaging speed is important, laser seam trackers must have a fast enough controller to accurately interpret the weld seam's location while providing the necessary closed-loop control to move the laser focusing head directly over the seam. Therefore, seam tracking accuracy is crucial, as is response time. Overall, seam tracking technology has advanced sufficiently to allow pipe manufacturers to utilize higher-quality laser beams to produce stainless steel pipe with improved formability. As a result, laser welding has found its niche, being used to reduce weld porosity and minimize weld profiles while maintaining or increasing welding speeds. Laser systems, such as diffusion-cooled slab lasers, have improved beam quality, further enhancing formability by reducing weld widths. This development has led to tighter dimensional control and the necessity for laser seam tracking in pipe mills. Thus, the success of the stainless steel pipe mill welding process depends on the integration of all individual technologies and must be approached as a complete system.

+86 18663958101

+86 18663958101